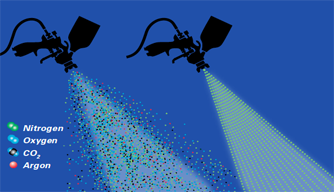

THE SMARTER WAY TO APPLY PAINT

Since 2010, We have been designing and developing custom Membrane Nitrogen Generators with heater controllers and heated hoses for automotive and industrial applications

100% Made in America, we are the leaders in Nitrogen generation for spray painting. Manufactured in Portland, Oregon, we have an international distribution network to support your needs.

With over 2000 units in operation internationally, we continue to supply a product that will increase efficiency and productivity, decrease costs and promote a cleaner environment

NITROGEN GENERATORS FOR SPRAY PAINTING

Decrease cycle time with an improvement of efficiency in your spray painting environment. Minimize paint wastage and improve finish quality with a product that is specifically designed to improve your paint shop performance. These units are commonly used in automotive collision facilities. They can also be used for paint applications on wood, fiberglass and other substrates that are spray painted.

COMPRESSED AIR AND NITROGEN HEATERS

The HeatPro 200 is a compressed air heater used to increase productivity and efficiency.

It is ideal for the spray-painting of both waterborne and solvent-based materials. The built-in set value and present value temperature controller allows maximum user control. Temperatures are adjustable for the application of different liquid materials. Ideal temperatures can be achieved for sealer, primer, base, and clear coats.

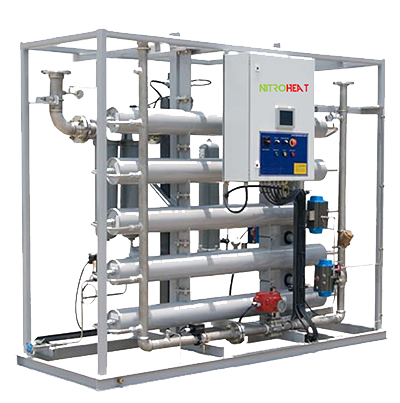

CUSTOM NITROGEN GENERATORS

Whatever your nitrogen requirements, we can supply a solution. From 1cfm plastic welders to 500cfm industrial plants, from 90% purity to 99.9% purity – we are your turnkey solution provider for your nitrogen requirements. Eliminate the usage of Nitrogen tanks and the consequential inconvenience of the logistics attached to their transportation and storage.

NITROGEN GENERATORS FOR TIRE FILLING

Need nitrogen for your tire filling stations? Don’t use expensive nitrogen tanks – our Nitrogen on Demand system will give you all the nitrogen you need 24 hours a day. Just connect to your compressed air and you have nitrogen available for all your tire filling needs.

NITROGEN PLASTIC WELDER

The Nitroweld NW-650 is a complete plastic welding station with built in temperature controllers including N2 and compressed air selection. This unit can be used with an external nitrogen supply (tank) or can be attached to a nitrogen generator. If used with a nitrogen cylinder, the built in selector allows the user to pre-heat and cool down with compressed air and ONLY use the N2 supply for the direct welding process.

NITROGEN GENERATORS FOR PLASTIC WELDING

The NW650-N2 is a mini nitrogen generator for plastic welding. This is a low-pressure low flow unit specifically designed to fit into a welding cart and replaces the need for tanked nitrogen.

Nitroheat is the exclusive supplier to the gomobile tires franchise for all its Nitrogen filling needs.

Nitroheat designed a custom wall mount unit that fits into the gomobile tires vans.

for more info see www.gomobiletires.com

The team at Nitroheat designed and installed the entire compressed air, filtration, receiver tanks and the nitrogen solution to meet the requirements of a mobile tire shop that can supply its clients with Nitrogen