Operations

The Nitromax system needs to be setup correctly to maximize the operation and performance. Adjustment of temperature and pressure are critical for optimum benefits. Please follow the instructions below to setup your paint gun and heater for the type of liquids being applied.

NITROMAX

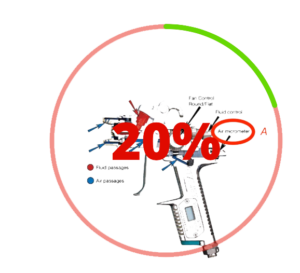

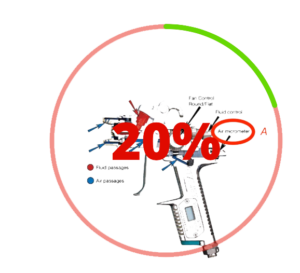

Reduce Pressure by 20%

Reduce Pressure by 20%

Atomization with the single nitrogen gas does not require as much pressure as atomization with compressed air

Reduce Fluid Feed by 20%

The improved transfer efficiency of heated nitrogen can cause an “over flow” of paint on the substrate.

CLOSE FLUID CONTROL – THEN OPEN 2 ½ TURNS

Mix 20% less paint

The increased transfer efficiency of A + B will result in lower paint utilization. THIS DOES NOT MEAN THAT YOU WILL HAVE LESS PAINT ON THE SUBSTRATE – THIS MEANS THAT YOU WILL BE WASTING LESS PAINT. (indicative in the drop in overspray)

HEATPRO

TEMPERATURE ADJUSTMENT

Press A/T button – press once to change the last digit, press twice to change second (middle) digit

Press UP or DOWN arrows until the desired temperature is reached

Press SET to save temperature.

![]()

NITROWELD

Temperature Adjustment – Airless Welder

The temperature adjustment on the left hand side of the machine operates with an on/off switch and incorporated temperature adjuster knob. Ensure that the airless welder is in the cradle when not in use.

Clockwise – Increase temp

Ant Clockwise – Decrease temp.

Temperature Adjustment – Hot N2 Welder

Clockwise – Increase temp

Anti Clockwise – decrease temp.

Adjust temperature as per the melting point of the material being welded.

Pre heat with compressed air if N2 tanks are used.

ALWAYS ALLOW HOT AIR WELDER TO COOL DOWN BEFORE SHUTTING OFF N2 OR COMPRESSED AIR.

Remember the following for an ideal weld:

Set correct Temperature

Hold rod at the correct Angle

Apply enough Pressure to gently allow the rod to fill into the substrate being welded.

SUBSTRATE MELTING TEMPERATURES

| Code | Plastic | Melting Temp °C |

|---|---|---|

| ABS | Acrylonitrile Butadiene Styrene | 350 |

| ABS/PC | Polymer alloy of above | 350 |

| PA | Polyamide (Nylon) | 400 |

| PBT | Polybutylene Terephtalate (POCAN) | 350 |

| PC | Polycarbonate | 350 |

| PE | Polyethylene | 300 |

| PP | Polypropylene | 300 |

| PUR | Polyurethane (Not all PUR is weldable) | |

| PVC | Polyvinyl Chloride | 300 |

| GRP/SMC | Glass Fiber Reinforced Plastics isNot weldable |